Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-AlN-B001Color :

White Grey Customized.Material : Aluminum Nitride

Shape : Square

Product Description:

Aluminum nitride ceramic substrate, high thermal conductivity, low coefficient of expansion, high strength, high temperature resistance, chemical resistance, high resistivity , low dielectric loss, is the ideal LSI heat dissipation board and packaging materials.

Aluminum Nitride is one of the few materials that offers electrical insulation and high thermal conductivity. This makes AlN extremely useful in high power electronic applications in heat sink and heat spreader applications.

ALN ceramics use heat resistant melt erosion and thermal shock resistance, can produce GaAs crystal crucible, Al evaporation pan, MHD power generation equipment and high temperature turbine corrosion resistant parts, using its optical properties can be used as an infrared window.

Size details:

| Aluminum Nitride Substrate Size | |||||||||

| Item NO. |

Length

(mm)

|

Width

(mm)

|

Thickness

(mm)

|

Purity | Item NO. |

Length

(mm)

|

Width

(mm)

|

Thickness

(mm)

|

Purity |

| CS-AlN-B001 | 50.8 | 50.8 | 0.12 ~ 1.0 | 99% | CS-AlN-B017 | 40 | 40 | 1 | 99% |

| CS-AlN-B002 | 76 | 76 | 0.12 ~ 1.0 | 99% | CS-AlN-B018 | 50 | 50 | 1 | 99% |

| CS-AlN-B003 | 101.6 | 101.6 | 0.12 ~ 1.0 | 99% | CS-AlN-B019 | 101.6 | 101.6 | 0.38 | 99% |

| CS-AlN-B004 | 114.3 | 114.3 | 0.12 ~ 1.0 | 99% | CS-AlN-B020 | 101.6 | 101.6 | 0.635 | 99% |

| CS-AlN-B005 | 127 | 127 | 0.12 ~ 1.0 | 99% | CS-AlN-B021 | 114 | 114 | 0.385 | 99% |

| CS-AlN-B006 | 140 | 190 | 0.12 ~ 1.0 | 99% | CS-AlN-B022 | 114.3 | 114.3 | 0.635 | 99% |

| CS-AlN-B007 | 60 | 48 | 0.12/0.2/0.25/0.38/0.3 | 99% | CS-AlN-B023 | 114 | 114 | 1 | 99% |

| CS-AlN-B008 | 19 | 14 | 1 | 99% | CS-AlN-B024 | 127 | 127 | 1 | 99% |

| CS-AlN-B009 | 25 | 20 | 1 | 99% | CS-AlN-B025 | 190.5 | 139 | 1 | 99% |

| CS-AlN-B010 | 28 | 22 | 1 | 99% | CS-AlN-B026 | 152.4 | 152.4 | 0.6 | 99% |

| CS-AlN-B011 | 42 | 29 | 1 | 99% | CS-AlN-B027 | 152.4 | 152.4 | 1 | 99% |

| CS-AlN-B012 | 22 | 17 | 0.6 | 99% | CS-AlN-B028 | 165 | 165 | 1 | 99% |

| CS-AlN-B013 | 30 | 6 | 1 | 99% | CS-AlN-B029 | 98 | 25 | 0.635 | 99% |

| CS-AlN-B014 | 3.6 | 3.6 | 0.385 | 99% | CS-AlN-B030 | 50 | 50 | 0.5 | 99% |

| CS-AlN-B015 | 10 | 10 | 1 | 99% | CS-AlN-B031 | 88 | 55 | 2 | 99% |

| CS-AlN-B016 | 30 | 30 | 1 | 99% | |||||

Features:

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) Stiffness texture

6) Used in all electric products, electric heating products and wear resistant machinery parts.

Applications:

High-power circuits, RF and microwave circuits, GaAs crystal crucible, Al evaporation pan, MHD power generation equipment.

Properties:

| Alumina Nitride (AlN) | ||||

| Item | AlN180 | AlN200 | AlN220 | Unit |

| Colour | Gray | Gray | Beige | |

| Density | 3.3 | 3.3 | 3.28 | g/cm3 |

| Flexural Strength | ≥350 | ≥350 | ≥350 | MPa |

| Compressive Strength | 2500 | 2500 | - | MPa |

| Elastic Modulus | 320 | 320 | 320 | GPa |

| Vickers Hardness (Load 500g) | 10 | 9.5 | 9 | HV0.5 |

| Coefficient of Line Thermal Expansion | 4.8 | 4.6 | 4.5 | 10-6K-1 |

| Thermal Conductivity(20℃) | 180 | 200 | 220 | W/m·K |

| Volume Resistance at 20°C | >1014 | >1014 | >1013 | cm |

| Dielectric Strength | ≥15 | ≥15 | ≥15 | KV/mm |

| Dielectric Constant (1MHz) | 9 | 8.8 | 8.6 | εr |

| Loss Tangent | 5 | 5 | 3 | 10-4 |

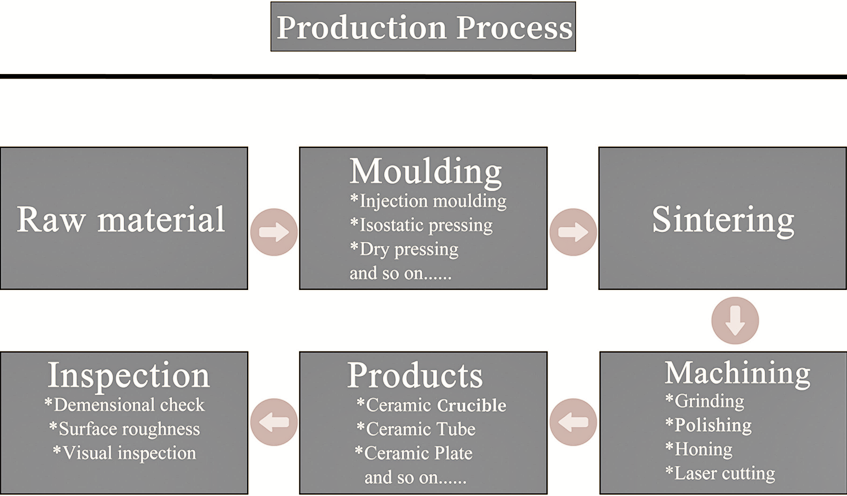

Production Process:

Packing:

Our Certificate:

FAQ

Q1: What is Aluminum Nitride(AlN)?

Aluminum Nitride (AlN) is a covalently bonded ceramic material formed from the two abundant elements, aluminum and nitrogen. It is highly stable in an atmosphere that is inert at temperatures over 2000°C and has a remarkable combination of properties, boasting high thermal conductivity and strong dielectric strength.T his makes it an indispensable material for thermal management and electrical applications.

Q2: What is Aluminium Nitride used for?

a. Heat sinks & Heat spreaders

b. Electrical insulators

c. Chucks and clamp rings for semiconductor processing equipment

d. Silicon wafer handling and processing

e. Substrates for electronic packages

f. Chip carriers for sensors and detectors

g. Laser heat management components

h. Molten metal fixtures

i. Packaging for microwave devices

Q3: Why is AlN a favored material for substrate and thermal management applications?

Aluminum Nitride is a one-of-a-kind ceramic material that offers both excellent thermal conductivity and high electrical resistivity. While Beryllium Oxide and cubic Boron Nitride also possess high thermal conductivity, usage of BeO is limited due to its toxicity and it is quite challenging to manufacture c-BN.

The capacity of a material to move heat while under the effect of a temperature differential is known as "thermal conductivity". In dielectrics such as AlN, heat transmission happens through lattice oscillations (or "phonons"). Elements having a straightforward composition, covalent bonding and low atomic mass normally demonstrate elevated thermal conductivity.

The thermal conductivity of a material is impacted by elements that hamper phonon dissemination. Such factors include temperature, impurities, pore size and placement, grain size, compositional homogeneity and alignment, all of which can significantly affect the lattice vibrations and, subsequently, the thermal conductivity.

The thermal conductivity of aluminium nitride, theoretically, is approximately 280 Wm-1K-1. The real thermal conductivity, on the other hand, is dependent on the processing parameters and the raw material quality. The incorporation of oxygen impurities into the lattice is a great disadvantage; as oxygen displaces nitrogen in the lattice, it forms vacancies that impede phonon propagation and scatter the phonons, thus leading to a decrease in thermal conductivity.

Q4. What information should we supply to get a quote?

Please offer the specification of ceramic boat for furnace, such as shape, dimension, quantity, application etc.

Q5. What type or material should we choose?

If you are not sure about the type/material needed, please kindly supply more details about working condition and application. Then our technical staff will check and offer you the most suitable type or material.

Q6. How can we place an order?

You can contact any sale person by email, Skype, WhatsApp, WeChat and so on.

And more details of the products you supplied will be helpful to get the targeted responses.

Q7. How long our order can be finished?

A mass of semi-finished products and standard sizes are available in stock, and according to the final confirm with the sales for bulk production or customized products.

Q8. What do you do on quality control?

For every batch, each step and finished products will be inspected when producing by QC department.

Q9. How can we get the sample?

Free samples can be supplied after communication, but freight is for your account.

Q10. Can you accept OEM/ODM?

Yes, your goods will be produced exactly according to your drawings or inquiry.

Contact information:

Ella Yu

Email:Ella@csceramic.com

Tel: 0086-731-23455639 Fax: 0086-731-23455639

Mobile / WhatsApp / WeChat: 0086-15377338375

ADD: Chashan Town Liling City Hunan Province ,China.

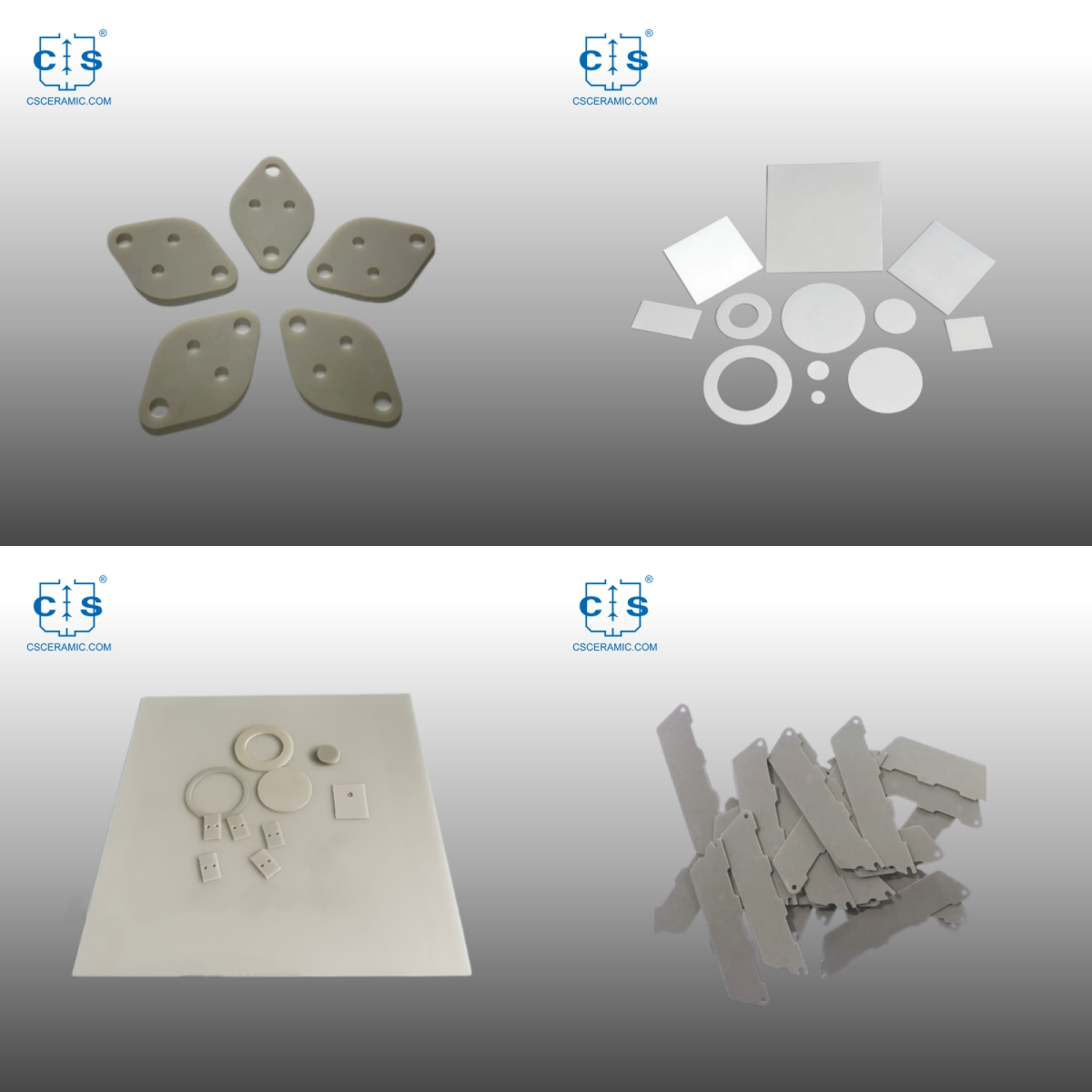

More Aluminum Nitride Substrate picture:

Next :

Aluminum Nitride Wafers High-Performance Metalized AlN Ceramic Substrate for HV/HP Devices

High-Performance Metalized AlN Ceramic Substrate for HV/HP Devices

The metalized aluminum nitride ceramic substrate is a versatile packaging solution for high-voltage, high-power devices in EVs, rail transit, smart grids, aerospace.

High-Temp Aluminum Nitride Heating Plate for Production, Analysis, Research

High-Temp Aluminum Nitride Heating Plate for Production, Analysis, Research

The aluminum nitride heating plate boasts high temp & corrosion resistance, high thermal conductivity, widely used in production, analysis, & research.

High-Resistivity Aluminum Nitride Plate Excellent Insulation & Thermal Conductivity

High-Resistivity Aluminum Nitride Plate Excellent Insulation & Thermal Conductivity

Aluminum nitride plate with excellent thermal conductivity, wear & corrosion resistance, ideal for high-temp environments.

Aluminum Nitride Wafers

Aluminum Nitride Wafers

AlN wafers offers high thermal conductivity for thermal management application. A variety of specifications available. Satisfying various technical request.

Customized Aluminum Nitride Sheets

Customized Aluminum Nitride Sheets

Aluminum nitride substrates offers high electrical insulation for a variety of electrical uses. A variety of specifications available. Satisfying various machining request.

PT/ Platinum crucible cover /lid for Volume 40μl /110μl sample cups suit for TA Instruments SDT 2960 Q600

PT/ Platinum crucible cover /lid for Volume 40μl /110μl sample cups suit for TA Instruments SDT 2960 Q600

D6.5mm Platinum/Pt Crucibles Platinum/Pt Sample cover for TA Instruments TA TGA Q5000 IR Sample Pans. Manufacturer for TA crucibles and DSC sample pans. TA Instruments good alternative sample cups.

500μl Ceramic Sample Pans for equivalent to TA 952018.91 for TA Instruments TGA 2950/2050 Q500 / Q50

500μl Ceramic Sample Pans for equivalent to TA 952018.91 for TA Instruments TGA 2950/2050 Q500 / Q50

952018.91 500μl Alumina crucibles for TA Instruments. Manufacturer for TA crucibles and DSC sample pans. TA Instruments good alternative sample pans.

95µl Platinum/PT crucible for PerKinElmer TA test and DSC TGA measurements. Manufacturer for PerkinElmer crucibles and sample pans. Thermal analysis consumables for dsc data analysis.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522